Русский[править]

Морфологические и синтаксические свойства[править]

| падеж | ед. ч. | мн. ч. |

|---|---|---|

| Им. | кантиле́вер | кантиле́веры |

| Р. | кантиле́вера | кантиле́веров |

| Д. | кантиле́веру | кантиле́верам |

| В. | кантиле́вер | кантиле́веры |

| Тв. | кантиле́вером | кантиле́верами |

| Пр. | кантиле́вере | кантиле́верах |

кан—ти—ле́—вер

Существительное, неодушевлённое, мужской род, 2-е склонение (тип склонения 1a по классификации А. А. Зализняка).

Корень: -кантилевер-.

Произношение[править]

- МФА: ед. ч. [kənʲtʲɪˈɫɛvʲɪr], мн. ч. [kənʲtʲɪˈɫɛvʲɪrɨ]

Семантические свойства[править]

Значение[править]

- техн. микромеханический зонд в атомно-силовом микроскопе ◆ Причем и сложившаяся на тот момент (в 1997 году) ситуация в отрасли оказалась на редкость благоприятной: в частности, признанный лидер рынка кантилеверов ― американская фирма Park Scientific Instruments ― умудрилась выпустить большую партию бракованных кантилеверов, что сильно пошатнуло ее имидж, снизило объемы продаж и образовало незаполненную «брешь», которую вполне мог заполнить российский новичок. «Микроскопический лидер», 22 января 2004 года // «Бизнес-журнал»

- морск. нефтегаз. выдвижная консоль, на которой расположен буровой комплекс морской буровой установки ◆ В кормовой части, в диаметральной плоскости, устанавливается кантилевер, на котором устанавливается буровая вышка и размещается оборудование бурового и технологического назначения. Б. Р. Лившиц и др., «Тенденции развития глубоководных самоподъёмных плавучих буровых установок», 2013 // «Судостроение», № 2

- техн. жарг. велосипедный консольный тормоз (чаще всего употребляется в отношении тормозов с подводом тросика сверху) ◆ Отсутствует пример употребления (см. рекомендации).

- спорт. приём в фигурном катании — скольжение на двух коньках, поставленных примерно в одну линию пятками друг к другу, с туловищем, уложенным горизонтально ◆ Отсутствует пример употребления (см. рекомендации).

Синонимы[править]

- —

- —

- кантилеверный тормоз

- кораблик Климкина

Антонимы[править]

Гиперонимы[править]

- зонд, балка

- консоль

- тормоз

- кораблик

Гипонимы[править]

Родственные слова[править]

| Ближайшее родство | |

Этимология[править]

От англ. cantilever ‘консоль, кронштейн; свободновисящий’, далее от ??

Фразеологизмы и устойчивые сочетания[править]

Перевод[править]

| Список переводов | |

Библиография[править]

- Шагалова Е. Н. Словарь новейших иностранных слов (конец XX — начало XXI вв.): более 3000 слов и словосочетаний. — М. : АСТ: Астрель, 2010. — 943, [1] с. — (Biblio). — ISBN 978-5-17-061488-2, ISBN 978-5-17-061488-2.

|

|

Для улучшения этой статьи желательно:

|

-

1

cantilever

cantilever beam

консольная бока

cantilever empennage

свободнонесущее хвостовое оперение

cantilever landing gear

консольное шасси

cantilever monoplane

свободнонесущий моноплан

cantilever wing

свободнонесущее крыло

English-Russian aviation dictionary > cantilever

-

2

cantilever

* * *

- cantilever

- n

Англо-русский строительный словарь.

Академик.ру.

2011.Англо-русский словарь строительных терминов > cantilever

-

3

cantilever

cantilever [ˊkæntɪli:və]

n

1)

стр.

консо́ль, кронште́йн; уко́сина

Англо-русский словарь Мюллера > cantilever

-

4

cantilever

Персональный Сократ > cantilever

-

5

cantilever

Кантилевер (консоль)

Название распространенной конструкции микроэлектромеханического зонда атомно-силового микроскопа. Представляет собой гибкую балку (175х40х4 мкм — усредненные данные) с определенным коэффициентом жесткости k (10-3 – 10 Н/м), на конце которой находится микроигла. Радиус закругления наконечника иглы может достигать 5 нм. Угол при вершине иглы изменяется от 20° до 70°.

Изображение кантилевера атомно-силового микроскопа, сделанное с помощью электронного микроскопа.

Англо-русский словарь по нанотехнологиям > cantilever

-

6

cantilever

Англо-русский технический словарь > cantilever

-

7

cantilever

консоль; консольная балка; консольная плита

English-Russian big polytechnic dictionary > cantilever

-

8

cantilever

1. n стр. консоль, кронштейн, укосина

2. n тех. рукав

English-Russian base dictionary > cantilever

-

9

cantilever

[ˈkæntɪli:və]

cantilever стр. консоль, кронштейн; укосина cantilever attr.: cantilever wing ав. свободнонесущее крыло cantilever attr.: cantilever wing ав. свободнонесущее крыло

English-Russian short dictionary > cantilever

-

10

cantilever

Англо-русский строительный словарь > cantilever

-

11

cantilever

Англо-русский синонимический словарь > cantilever

-

12

cantilever

1) консоль; консольная балка; укосина

English-Russian scientific dictionary > cantilever

-

13

cantilever

English-Russian dictionary on nuclear energy > cantilever

-

14

cantilever

Большой англо-русский и русско-английский словарь > cantilever

-

15

cantilever

Англо-русский словарь технических терминов > cantilever

-

16

cantilever

noun

1) constr. консоль, кронштейн; укосина

2) (

attr.

) cantilever wing

aeron.

свободнонесущее крыло

* * *

(n) консоль; кронштейн; укосина

* * *

строконсоль, кронштейн; укосина

* * *

[can·ti·le·ver || ‘kæntɪliːvə]

консоль, кронштейн, укосина* * *

кронштейн

укосина

* * *

строит.

консольНовый англо-русский словарь > cantilever

-

17

cantilever

консоль; укосина; рычаг; кронштейн; кантилевер; стрела

Англо-русский словарь по машиностроению > cantilever

-

18

cantilever

консоль; вынесенный кронштейн; консольный ; свободнонесущий

Englsh-Russian aviation and space dictionary > cantilever

-

19

cantilever

- консоль

Англо-русский словарь нормативно-технической терминологии > cantilever

-

20

cantilever

[ʹkæntı͵li:və]

1)

консоль, кронштейн, укосина

НБАРС > cantilever

Страницы

- Следующая →

- 1

- 2

- 3

- 4

- 5

- 6

- 7

См. также в других словарях:

-

cantilever — [ kɑ̃tiləvɛr; kɑ̃tilevɶr ] adj. inv. et n. m. • 1883; mot angl., de cant « rebord » et lever « levier » ♦ Qui est suspendu en porte à faux (sans câbles). Pont cantilever. Suspension cantilever. N. m. Aile d avion en cantilever. ● cantilever… … Encyclopédie Universelle

-

Cantilever — (englisch für verschiedene waagerechte, einseitig gelagerte und auskragende Bauteile) bezeichnet: den „Lesekopf“ von IBM Millipede, siehe Millipede die Messnadel eines Rasterkraftmikroskops, siehe Cantilever (Mikroskop) eine Bauart für eine… … Deutsch Wikipedia

-

cantilever — cantilevér s. n. Trimis de siveco, 10.08.2004. Sursa: Dicţionar ortografic CANTILEVÉR adj., s.n. (Sistem de suspensie) care nu are o susţinere directă. // s.n. (constr.) Tip de pod metalic ale cărui grinzi principale nu au o susţinere directă… … Dicționar Român

-

cantilever — ► NOUN 1) a long projecting beam or girder fixed at only one end, used chiefly in bridge construction. 2) a bracket or beam projecting from a wall to support a balcony, cornice, etc. ► VERB ▪ support by a cantilever or cantilevers. ORIGIN of… … English terms dictionary

-

Cantilever — Can ti*lev er, n. Same as {Cantalever}. [1913 Webster] … The Collaborative International Dictionary of English

-

Cantilever — (Cantaliver, engl., spr. känntĭlĭwer, känntǟlĭwer), vorspringender Träger, Ausleger; s. Brücke, S. 479 … Meyers Großes Konversations-Lexikon

-

cantilever — cantiléver (ingl.) m. Voladizo. * * * ► masculino CONSTRUCCIÓN Voladizo … Enciclopedia Universal

-

cantilever — 1660s, probably from CANT (Cf. cant) (2) + LEVER (Cf. lever), but earliest form (c.1610) was cantlapper. First element also may be Sp. can dog, architect s term for an end of timber jutting out of a wall, on which beams rested … Etymology dictionary

-

cantilever — Cantilever Кантилевер (консоль) Название распространенной конструкции микроэлектромеханического зонда атомно силового микроскопа. Представляет собой гибкую балку (175х40х4 мкм усредненные данные) с определенным коэффициентом жесткости k (10 3 … Толковый англо-русский словарь по нанотехнологии. — М.

-

cantilever — [kant′ l ē΄vər, kant′ lev΄ər] n. [as if < CANT2 + I + LEVER, but < ?] 1. a large bracket or block projecting from a wall to support a balcony, cornice, etc. 2. a projecting beam or structure supported at only one end, that is anchored as to … English World dictionary

-

Cantilever — For the figure skating element, see Cantilever (figure skating). A schematic image of two cantilevers. The top example has a full moment connection (like a horizontal flag pole bolted to the side of a building). The bottom example is created by… … Wikipedia

From Wikipedia, the free encyclopedia

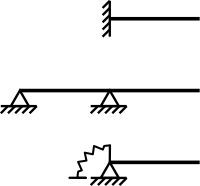

A schematic image of three types of cantilever. The top example has a full moment connection (like a horizontal flagpole bolted to the side of a building). The middle example is created by an extension of a simple supported beam (such as the way a diving board is anchored and extends over the edge of a swimming pool). The bottom example is created by adding a Robin boundary condition to the beam element, which essentially adds an elastic spring to the end board. The top and bottom example may be considered structurally equivalent, depending on the effective stiffness of the spring and beam element.

A cantilever is a rigid structural element that extends horizontally and is supported at only one end. Typically it extends from a flat vertical surface such as a wall, to which it must be firmly attached. Like other structural elements, a cantilever can be formed as a beam, plate, truss, or slab.

When subjected to a structural load at its far, unsupported end, the cantilever carries the load to the support where it applies a shear stress and a bending moment.[1]

Cantilever construction allows overhanging structures without additional support.

In bridges, towers, and buildings[edit]

Cantilevers are widely found in construction, notably in cantilever bridges and balconies (see corbel). In cantilever bridges, the cantilevers are usually built as pairs, with each cantilever used to support one end of a central section. The Forth Bridge in Scotland is an example of a cantilever truss bridge. A cantilever in a traditionally timber framed building is called a jetty or forebay. In the southern United States, a historic barn type is the cantilever barn of log construction.

Temporary cantilevers are often used in construction.

The partially constructed structure creates a cantilever, but the completed structure does not act as a cantilever.

This is very helpful when temporary supports, or falsework, cannot be used to support the structure while it is being built (e.g., over a busy roadway or river, or in a deep valley).

Therefore, some truss arch bridges (see Navajo Bridge) are built from each side as cantilevers until the spans reach each other and are then jacked apart to stress them in compression before finally joining.

Nearly all cable-stayed bridges are built using cantilevers as this is one of their chief advantages.

Many box girder bridges are built segmentally, or in short pieces.

This type of construction lends itself well to balanced cantilever construction where the bridge is built in both directions from a single support.

These structures rely heavily on torque and rotational equilibrium for their stability.

In an architectural application, Frank Lloyd Wright’s Fallingwater used cantilevers to project large balconies.

The East Stand at Elland Road Stadium in Leeds was, when completed, the largest cantilever stand in the world[2] holding 17,000 spectators.

The roof built over the stands at Old Trafford uses a cantilever so that no supports will block views of the field.

The old (now demolished) Miami Stadium had a similar roof over the spectator area.

The largest cantilevered roof in Europe is located at St James’ Park in Newcastle-Upon-Tyne, the home stadium of Newcastle United F.C.[3][4]

Less obvious examples of cantilevers are free-standing (vertical) radio towers without guy-wires, and chimneys, which resist being blown over by the wind through cantilever action at their base.

-

This concrete bridge temporarily functions as a set of two balanced cantilevers during construction – with further cantilevers jutting out to support formwork.

-

A double jettied building in Cambridge, England

-

Cantilever occurring in the game «Jenga»

-

-

This radiograph of a «bridge» dental restoration features a cantilevered crown to the left.

-

Ronan Point: Structural failure of part of floors cantilevered from a central shaft.

Aircraft[edit]

The pioneering Junkers J 1 all-metal monoplane of 1915, the first aircraft to fly with cantilever wings

The cantilever is commonly used in the wings of fixed-wing aircraft. Early aircraft had light structures which were braced with wires and struts. However, these introduced aerodynamic drag which limited performance. While it is heavier, the cantilever avoids this issue and allows the plane to fly faster.

Hugo Junkers pioneered the cantilever wing in 1915. Only a dozen years after the Wright Brothers’ initial flights, Junkers endeavored to eliminate virtually all major external bracing members in order to decrease airframe drag in flight. The result of this endeavor was the Junkers J 1 pioneering all-metal monoplane of late 1915, designed from the start with all-metal cantilever wing panels. About a year after the initial success of the Junkers J 1, Reinhold Platz of Fokker also achieved success with a cantilever-winged sesquiplane built instead with wooden materials, the Fokker V.1.

In the cantilever wing, one or more strong beams, called spars, run along the span of the wing. The end fixed rigidly to the central fuselage is known as the root and the far end as the tip. In flight, the wings generate lift and the spars carry this load through to the fuselage.

To resist horizontal shear stress from either drag or engine thrust, the wing must also form a stiff cantilever in the horizontal plane. A single-spar design will usually be fitted with a second smaller drag-spar nearer the trailing edge, braced to the main spar via additional internal members or a stressed skin. The wing must also resist twisting forces, achieved by cross-bracing or otherwise stiffening the main structure.

Cantilever wings require much stronger and heavier spars than would otherwise be needed in a wire-braced design. However, as the speed of the aircraft increases, the drag of the bracing increases sharply, while the wing structure must be strengthened, typically by increasing the strength of the spars and the thickness of the skinning. At speeds of around 200 miles per hour (320 km/h) the drag of the bracing becomes excessive and the wing strong enough to be made a cantilever without excess weight penalty. Increases in engine power through the late 1920s and early 1930s raised speeds through this zone and by the late 1930s cantilever wings had almost wholly superseded braced ones.[5] Other changes such as enclosed cockpits, retractable undercarriage, landing flaps and stressed-skin construction furthered the design revolution, with the pivotal moment widely acknowledged to be the MacRobertson England-Australia air race of 1934, which was won by a de Havilland DH.88 Comet.[6]

Currently, cantilever wings are almost universal with bracing only being used for some slower aircraft where a lighter weight is prioritized over speed, such as in the ultralight class.

In microelectromechanical systems[edit]

SEM image of a used AFM cantilever

Cantilevered beams are the most ubiquitous structures in the field of microelectromechanical systems (MEMS). An early example of a MEMS cantilever is the Resonistor,[7][8] an electromechanical monolithic resonator. MEMS cantilevers are commonly fabricated from silicon (Si), silicon nitride (Si3N4), or polymers.

The fabrication process typically involves undercutting the cantilever structure to release it, often with an anisotropic wet or dry etching technique. Without cantilever transducers, atomic force microscopy would not be possible.

A large number of research groups are attempting to develop cantilever arrays as biosensors for medical diagnostic applications. MEMS cantilevers are also finding application as radio frequency filters and resonators.

The MEMS cantilevers are commonly made as unimorphs or bimorphs.

Two equations are key to understanding the behavior of MEMS cantilevers.

The first is Stoney’s formula, which relates cantilever end deflection δ to applied stress σ:

where

The second is the formula relating the cantilever spring constant

where

The frequency shift can be measured with exquisite accuracy using heterodyne techniques and is the basis of ac-coupled cantilever sensors.

The principal advantage of MEMS cantilevers is their cheapness and ease of fabrication in large arrays.

The challenge for their practical application lies in the square and cubic dependences of cantilever performance specifications on dimensions.

These superlinear dependences mean that cantilevers are quite sensitive to variation in process parameters, particularly the thickness as this is generally difficult to accurately measure.[9] However, it has been shown that microcantilever thicknesses can be precisely measured and that this variation can be quantified.[10] Controlling residual stress can also be difficult.

MEMS cantilever in resonance[11]

Chemical sensor applications[edit]

A chemical sensor can be obtained by coating a recognition receptor layer over the upper side of a microcantilever beam.[12] A typical application is the immunosensor based on an antibody layer that interacts selectively with a particular immunogen and reports about its content in a specimen. In the static mode of operation, the sensor response is represented by the beam bending with respect to a reference microcantilever. Alternatively, microcantilever sensors can be operated in the dynamic mode. In this case, the beam vibrates at its resonance frequency and a variation in this parameter indicates the concentration of the analyte. Recently, microcantilevers have been fabricated that are porous, allowing for a much larger surface area for analyte to bind to, increasing sensitivity by raising the ratio of the analyte mass to the device mass.[13] Surface stress on microcantilever, due to receptor-target binding, which produces cantilever deflection can be analyzed using optical methods like laser interferometry. Zhao et al., also showed that by changing the attachment protocol of the receptor on the microcantilever surface, the sensitivity can be further improved when the surface stress generated on the microcantilever is taken as the sensor signal.[14]

See also[edit]

- Applied mechanics

- Cantilever bicycle brakes

- Cantilever bicycle frame

- Cantilever chair

- Cantilever method

- Cantilevered stairs

- Corbel arch

- Euler–Bernoulli beam theory

- Grand Canyon Skywalk

- Knudsen force in the context of microcantilevers

- Orthodontics

- Statics

References[edit]

- ^ Hool, George A.; Johnson, Nathan Clarke (1920). «Elements of Structural Theory — Definitions». Handbook of Building Construction (Google Books). Vol. 1 (1st ed.). New York: McGraw-Hill. p. 2. Retrieved 2008-10-01.

A cantilever beam is a beam having one end rigidly fixed and the other end free.

- ^ «GMI Construction wins £5.5M Design and Build Contract for Leeds United Football Club’s Elland Road East Stand». Construction News. 6 February 1992. Retrieved 24 September 2012.

- ^ IStructE The Structural Engineer Volume 77/No 21, 2 November 1999. James’s Park a redevelopment challenge

- ^ The Architects’ Journal Existing stadiums: St James’ Park, Newcastle. 1 July 2005

- ^ Stevens, James Hay; The Shape of the Aeroplane, Hutchinson, 1953. pp.78 ff.

- ^ Davy, M.J.B.; Aeronautics – Heavier-Than-Air Aircraft, Part I, Historical Survey, Revised edition, Science Museum/HMSO, December 1949. p.57.

- ^ ELECTROMECHANICAL MONOLITHIC RESONATOR, US Pat.3417249 — Filed April 29, 1966

- ^ R.J. Wilfinger, P. H. Bardell and D. S. Chhabra: The resonistor a frequency selective device utilizing the mechanical resonance of a silicon substrate, IBM J. 12, 113–118 (1968)

- ^ P. M. Kosaka, J. Tamayo, J. J. Ruiz, S. Puertas, E. Polo, V. Grazu, J. M. de la Fuente and M. Calleja: Tackling reproducibility in microcantilever biosensors: a statistical approach for sensitive and specific end-point detection of immunoreactions, Analyst 138, 863–872 (2013)

- ^ A. R. Salmon, M. J. Capener, J. J. Baumberg and S. R. Elliott: Rapid microcantilever-thickness determination by optical interferometry, Measurement Science and Technology 25, 015202 (2014)

- ^ P. C. Fletcher, Y. Xu, P. Gopinath, J. Williams, B. W. Alphenaar, R. D. Bradshaw, R. S. Keynton, «Piezoresistive Geometry for Maximizing Microcantilever Array Sensitivity,» presented at the IEEE Sensors, Lecce, Italy, 2008.

- ^ Bǎnicǎ, Florinel-Gabriel (2012). Chemical Sensors and Biosensors:Fundamentals and Applications. Chichester, UK: John Wiley & Sons. p. 576. ISBN 9781118354230.

- ^ Noyce, Steven G.; Vanfleet, Richard R.; Craighead, Harold G.; Davis, Robert C. (1999-02-22). «High surface-area carbon microcantilevers». Nanoscale Advances. 1 (3): 1148–1154. doi:10.1039/C8NA00101D. PMC 9418787. PMID 36133213.

- ^ Yue Zhao,Agnivo Gosai, Pranav Shrotriya : Effect of Receptor Attachment on Sensitivity of Label Free Microcantilever Based Biosensor Using Malachite Green Aptamer https://doi.org/10.1016/j.snb.2019.126963

[1]

Sources[edit]

- Inglis, Simon: Football Grounds of Britain. CollinsWillow, 1996. page 206.

- Madou, Marc J (2002). Fundamentals of Microfabrication. Taylor & Francis. ISBN 0-8493-0826-7.

- Roth, Leland M (1993). Understanding Architecture: Its Elements History and Meaning. Oxford, UK: Westview Press. pp. 23–4. ISBN 0-06-430158-3.

- Sarid, Dror (1994). Scanning Force Microscopy. Oxford University Press. ISBN 0-19-509204-X.

- ^ Kurhekar, Anil Sudhakar (2018-08-03). «On stiction mechanism of bulk micro-machined micro-mechanical structures». AIP Conference Proceedings. 1992 (1): 030014. doi:10.1063/1.5047965. ISSN 0094-243X.

From Wikipedia, the free encyclopedia

A schematic image of three types of cantilever. The top example has a full moment connection (like a horizontal flagpole bolted to the side of a building). The middle example is created by an extension of a simple supported beam (such as the way a diving board is anchored and extends over the edge of a swimming pool). The bottom example is created by adding a Robin boundary condition to the beam element, which essentially adds an elastic spring to the end board. The top and bottom example may be considered structurally equivalent, depending on the effective stiffness of the spring and beam element.

A cantilever is a rigid structural element that extends horizontally and is supported at only one end. Typically it extends from a flat vertical surface such as a wall, to which it must be firmly attached. Like other structural elements, a cantilever can be formed as a beam, plate, truss, or slab.

When subjected to a structural load at its far, unsupported end, the cantilever carries the load to the support where it applies a shear stress and a bending moment.[1]

Cantilever construction allows overhanging structures without additional support.

In bridges, towers, and buildings[edit]

Cantilevers are widely found in construction, notably in cantilever bridges and balconies (see corbel). In cantilever bridges, the cantilevers are usually built as pairs, with each cantilever used to support one end of a central section. The Forth Bridge in Scotland is an example of a cantilever truss bridge. A cantilever in a traditionally timber framed building is called a jetty or forebay. In the southern United States, a historic barn type is the cantilever barn of log construction.

Temporary cantilevers are often used in construction.

The partially constructed structure creates a cantilever, but the completed structure does not act as a cantilever.

This is very helpful when temporary supports, or falsework, cannot be used to support the structure while it is being built (e.g., over a busy roadway or river, or in a deep valley).

Therefore, some truss arch bridges (see Navajo Bridge) are built from each side as cantilevers until the spans reach each other and are then jacked apart to stress them in compression before finally joining.

Nearly all cable-stayed bridges are built using cantilevers as this is one of their chief advantages.

Many box girder bridges are built segmentally, or in short pieces.

This type of construction lends itself well to balanced cantilever construction where the bridge is built in both directions from a single support.

These structures rely heavily on torque and rotational equilibrium for their stability.

In an architectural application, Frank Lloyd Wright’s Fallingwater used cantilevers to project large balconies.

The East Stand at Elland Road Stadium in Leeds was, when completed, the largest cantilever stand in the world[2] holding 17,000 spectators.

The roof built over the stands at Old Trafford uses a cantilever so that no supports will block views of the field.

The old (now demolished) Miami Stadium had a similar roof over the spectator area.

The largest cantilevered roof in Europe is located at St James’ Park in Newcastle-Upon-Tyne, the home stadium of Newcastle United F.C.[3][4]

Less obvious examples of cantilevers are free-standing (vertical) radio towers without guy-wires, and chimneys, which resist being blown over by the wind through cantilever action at their base.

-

This concrete bridge temporarily functions as a set of two balanced cantilevers during construction – with further cantilevers jutting out to support formwork.

-

A double jettied building in Cambridge, England

-

Cantilever occurring in the game «Jenga»

-

-

This radiograph of a «bridge» dental restoration features a cantilevered crown to the left.

-

Ronan Point: Structural failure of part of floors cantilevered from a central shaft.

Aircraft[edit]

The pioneering Junkers J 1 all-metal monoplane of 1915, the first aircraft to fly with cantilever wings

The cantilever is commonly used in the wings of fixed-wing aircraft. Early aircraft had light structures which were braced with wires and struts. However, these introduced aerodynamic drag which limited performance. While it is heavier, the cantilever avoids this issue and allows the plane to fly faster.

Hugo Junkers pioneered the cantilever wing in 1915. Only a dozen years after the Wright Brothers’ initial flights, Junkers endeavored to eliminate virtually all major external bracing members in order to decrease airframe drag in flight. The result of this endeavor was the Junkers J 1 pioneering all-metal monoplane of late 1915, designed from the start with all-metal cantilever wing panels. About a year after the initial success of the Junkers J 1, Reinhold Platz of Fokker also achieved success with a cantilever-winged sesquiplane built instead with wooden materials, the Fokker V.1.

In the cantilever wing, one or more strong beams, called spars, run along the span of the wing. The end fixed rigidly to the central fuselage is known as the root and the far end as the tip. In flight, the wings generate lift and the spars carry this load through to the fuselage.

To resist horizontal shear stress from either drag or engine thrust, the wing must also form a stiff cantilever in the horizontal plane. A single-spar design will usually be fitted with a second smaller drag-spar nearer the trailing edge, braced to the main spar via additional internal members or a stressed skin. The wing must also resist twisting forces, achieved by cross-bracing or otherwise stiffening the main structure.

Cantilever wings require much stronger and heavier spars than would otherwise be needed in a wire-braced design. However, as the speed of the aircraft increases, the drag of the bracing increases sharply, while the wing structure must be strengthened, typically by increasing the strength of the spars and the thickness of the skinning. At speeds of around 200 miles per hour (320 km/h) the drag of the bracing becomes excessive and the wing strong enough to be made a cantilever without excess weight penalty. Increases in engine power through the late 1920s and early 1930s raised speeds through this zone and by the late 1930s cantilever wings had almost wholly superseded braced ones.[5] Other changes such as enclosed cockpits, retractable undercarriage, landing flaps and stressed-skin construction furthered the design revolution, with the pivotal moment widely acknowledged to be the MacRobertson England-Australia air race of 1934, which was won by a de Havilland DH.88 Comet.[6]

Currently, cantilever wings are almost universal with bracing only being used for some slower aircraft where a lighter weight is prioritized over speed, such as in the ultralight class.

In microelectromechanical systems[edit]

SEM image of a used AFM cantilever

Cantilevered beams are the most ubiquitous structures in the field of microelectromechanical systems (MEMS). An early example of a MEMS cantilever is the Resonistor,[7][8] an electromechanical monolithic resonator. MEMS cantilevers are commonly fabricated from silicon (Si), silicon nitride (Si3N4), or polymers.

The fabrication process typically involves undercutting the cantilever structure to release it, often with an anisotropic wet or dry etching technique. Without cantilever transducers, atomic force microscopy would not be possible.

A large number of research groups are attempting to develop cantilever arrays as biosensors for medical diagnostic applications. MEMS cantilevers are also finding application as radio frequency filters and resonators.

The MEMS cantilevers are commonly made as unimorphs or bimorphs.

Two equations are key to understanding the behavior of MEMS cantilevers.

The first is Stoney’s formula, which relates cantilever end deflection δ to applied stress σ:

where

The second is the formula relating the cantilever spring constant

where

The frequency shift can be measured with exquisite accuracy using heterodyne techniques and is the basis of ac-coupled cantilever sensors.

The principal advantage of MEMS cantilevers is their cheapness and ease of fabrication in large arrays.

The challenge for their practical application lies in the square and cubic dependences of cantilever performance specifications on dimensions.

These superlinear dependences mean that cantilevers are quite sensitive to variation in process parameters, particularly the thickness as this is generally difficult to accurately measure.[9] However, it has been shown that microcantilever thicknesses can be precisely measured and that this variation can be quantified.[10] Controlling residual stress can also be difficult.

MEMS cantilever in resonance[11]

Chemical sensor applications[edit]

A chemical sensor can be obtained by coating a recognition receptor layer over the upper side of a microcantilever beam.[12] A typical application is the immunosensor based on an antibody layer that interacts selectively with a particular immunogen and reports about its content in a specimen. In the static mode of operation, the sensor response is represented by the beam bending with respect to a reference microcantilever. Alternatively, microcantilever sensors can be operated in the dynamic mode. In this case, the beam vibrates at its resonance frequency and a variation in this parameter indicates the concentration of the analyte. Recently, microcantilevers have been fabricated that are porous, allowing for a much larger surface area for analyte to bind to, increasing sensitivity by raising the ratio of the analyte mass to the device mass.[13] Surface stress on microcantilever, due to receptor-target binding, which produces cantilever deflection can be analyzed using optical methods like laser interferometry. Zhao et al., also showed that by changing the attachment protocol of the receptor on the microcantilever surface, the sensitivity can be further improved when the surface stress generated on the microcantilever is taken as the sensor signal.[14]

See also[edit]

- Applied mechanics

- Cantilever bicycle brakes

- Cantilever bicycle frame

- Cantilever chair

- Cantilever method

- Cantilevered stairs

- Corbel arch

- Euler–Bernoulli beam theory

- Grand Canyon Skywalk

- Knudsen force in the context of microcantilevers

- Orthodontics

- Statics

References[edit]

- ^ Hool, George A.; Johnson, Nathan Clarke (1920). «Elements of Structural Theory — Definitions». Handbook of Building Construction (Google Books). Vol. 1 (1st ed.). New York: McGraw-Hill. p. 2. Retrieved 2008-10-01.

A cantilever beam is a beam having one end rigidly fixed and the other end free.

- ^ «GMI Construction wins £5.5M Design and Build Contract for Leeds United Football Club’s Elland Road East Stand». Construction News. 6 February 1992. Retrieved 24 September 2012.

- ^ IStructE The Structural Engineer Volume 77/No 21, 2 November 1999. James’s Park a redevelopment challenge

- ^ The Architects’ Journal Existing stadiums: St James’ Park, Newcastle. 1 July 2005

- ^ Stevens, James Hay; The Shape of the Aeroplane, Hutchinson, 1953. pp.78 ff.

- ^ Davy, M.J.B.; Aeronautics – Heavier-Than-Air Aircraft, Part I, Historical Survey, Revised edition, Science Museum/HMSO, December 1949. p.57.

- ^ ELECTROMECHANICAL MONOLITHIC RESONATOR, US Pat.3417249 — Filed April 29, 1966

- ^ R.J. Wilfinger, P. H. Bardell and D. S. Chhabra: The resonistor a frequency selective device utilizing the mechanical resonance of a silicon substrate, IBM J. 12, 113–118 (1968)

- ^ P. M. Kosaka, J. Tamayo, J. J. Ruiz, S. Puertas, E. Polo, V. Grazu, J. M. de la Fuente and M. Calleja: Tackling reproducibility in microcantilever biosensors: a statistical approach for sensitive and specific end-point detection of immunoreactions, Analyst 138, 863–872 (2013)

- ^ A. R. Salmon, M. J. Capener, J. J. Baumberg and S. R. Elliott: Rapid microcantilever-thickness determination by optical interferometry, Measurement Science and Technology 25, 015202 (2014)

- ^ P. C. Fletcher, Y. Xu, P. Gopinath, J. Williams, B. W. Alphenaar, R. D. Bradshaw, R. S. Keynton, «Piezoresistive Geometry for Maximizing Microcantilever Array Sensitivity,» presented at the IEEE Sensors, Lecce, Italy, 2008.

- ^ Bǎnicǎ, Florinel-Gabriel (2012). Chemical Sensors and Biosensors:Fundamentals and Applications. Chichester, UK: John Wiley & Sons. p. 576. ISBN 9781118354230.

- ^ Noyce, Steven G.; Vanfleet, Richard R.; Craighead, Harold G.; Davis, Robert C. (1999-02-22). «High surface-area carbon microcantilevers». Nanoscale Advances. 1 (3): 1148–1154. doi:10.1039/C8NA00101D. PMC 9418787. PMID 36133213.

- ^ Yue Zhao,Agnivo Gosai, Pranav Shrotriya : Effect of Receptor Attachment on Sensitivity of Label Free Microcantilever Based Biosensor Using Malachite Green Aptamer https://doi.org/10.1016/j.snb.2019.126963

[1]

Sources[edit]

- Inglis, Simon: Football Grounds of Britain. CollinsWillow, 1996. page 206.

- Madou, Marc J (2002). Fundamentals of Microfabrication. Taylor & Francis. ISBN 0-8493-0826-7.

- Roth, Leland M (1993). Understanding Architecture: Its Elements History and Meaning. Oxford, UK: Westview Press. pp. 23–4. ISBN 0-06-430158-3.

- Sarid, Dror (1994). Scanning Force Microscopy. Oxford University Press. ISBN 0-19-509204-X.

- ^ Kurhekar, Anil Sudhakar (2018-08-03). «On stiction mechanism of bulk micro-machined micro-mechanical structures». AIP Conference Proceedings. 1992 (1): 030014. doi:10.1063/1.5047965. ISSN 0094-243X.

консоль, кронштейн, укосина

существительное

- стр. консоль, кронштейн, укосина

- тех. рукав (станка)

Мои примеры

Словосочетания

cantilever bridge — консольный мост

beam extends in cantilever — балка установлена консольно

to support as a cantilever — закреплять консольно

cantilever of a crane — стрела крана

cantilever girder — консольная балка

cantilever crane — консольный кран-перегружатель; кран на козлах со стрелами; консольный кран

cantilever extension of control — развитие опорной сети в районе, где отсутствуют тригонометрические пункты

cantilever fatigue test — испытание на усталость консольно закреплённого образца

cantilever fatigue testing machine — консольная машина для испытания на усталость

cantilever fitted — консольно закреплённый

Примеры с переводом

Frank Lloyd Wright liked to cantilever his buildings

Фрэнк Ллойд Райт любил применять в своих зданиях консольные балки.

Примеры, ожидающие перевода

The porch is supported by steel cantilevers.

The balcony cantilevers over the terrace below.

Для того чтобы добавить вариант перевода, кликните по иконке ☰, напротив примера.

Возможные однокоренные слова

cantilevered — заделанный одним концом, консольный, свободнонесущий

Формы слова

noun

ед. ч.(singular): cantilever

мн. ч.(plural): cantilevers

Бесплатный переводчик онлайн с английского на русский

Хотите общаться в чатах с собеседниками со всего мира, понимать, о чем поет Билли Айлиш, читать английские сайты на русском? PROMT.One мгновенно переведет ваш текст с английского на русский и еще на 20+ языков.

Точный перевод с транскрипцией

С помощью PROMT.One наслаждайтесь точным переводом с английского на русский, а для слов и фраз смотрите английскую транскрипцию, произношение и варианты переводов с примерами употребления в разных контекстах. Бесплатный онлайн-переводчик PROMT.One — достойная альтернатива Google Translate и другим сервисам, предоставляющим перевод с английского на русский и с русского на английский.

Нужно больше языков?

PROMT.One бесплатно переводит онлайн с английского на азербайджанский, арабский, греческий, иврит, испанский, итальянский, казахский, китайский, корейский, немецкий, португальский, татарский, турецкий, туркменский, узбекский, украинский, финский, французский, эстонский и японский.

Фигурное катание — невероятно красивый и технически сложный вид спорта. Номер фигуриста состоит из прыжков, вращений и пируэтов, которые объединяют между собой простые связующие элементы. Одним из таких является кантилевер в фигурном катании.

Содержание

- 1 История появления кантилевера

- 2 Тип элемента

- 3 Сложность выполнения

- 4 Разновидности кантилевера в фигурном катании

История появления кантилевера

Изобрели такой способ скольжения по льду американские фигуристы, которые выступали под псевдонимом «Фрик и Фрак». В отечественном спорте кантилеверная связка стала визитной карточкой Ильи Климкина. Позже такой способ скольжения стали называть его именем.

Тип элемента

Характерная особенность кантилевера в фигурном катании — это спиралевидные движения, которые исполняются в такт музыки. При этом фигурист держит ноги в позиции параллельно друг другу, колени согнуты, а торс наклоняется максимально назад.

До 2012 года судьи не выставляли оценку за связующие компоненты номера. В настоящее время оценивается так называемая «хореографическая дорожка», состоящая из разнообразных связок между сложными элементами во время выступления.

Одним из способов вращения по спирали являются различные виды корабликов. Особенность их исполнения заключается в параллельной постановке ног пятками друг другу. Стойка фигуриста при этом напоминает вторую танцевальную позицию.

Важно! Красиво и правильно выполненное, с технической точки зрения, соединение прыжков является показателем мастерства фигуриста.

Сложность выполнения

Изначально кораблик в фигурном катании осуществлялся в традиционной позе с выпрямленными ногами и торсом. Коньки при этом идут друг за другом: у одного передний ход, у другого — задний.

Позже техника стала усовершенствоваться, и возникли различные варианты связок.

Исполнение всех трюков на льду требует специальной подготовки и тренерского контроля!

Разновидности кантилевера в фигурном катании

Имеются следующие виды этого элемента:

- Бести. Движение на коньках происходит в сильном присяде. Своеобразной фишкой исполнения этого вида кораблика был у Натальи Бестемьяновой, советской фигуристки по спортивным танцам на льду, ставшей знаменитой в 80-е годы.

- Бауэр. Кататься на катке нужно так, чтобы ноги находились не во второй, а в четвёртой позиции. При этом передний конёк двигается на внешнем ребре, а задний — на внутренней стороне. Прославила такую связку немецкая фигуристка Ина Бауэр.

- Кораблик Климкина, или кантилевер. Пример наиболее сложного соединительного элемента. Скольжение с горизонтально расположенным торсом стало обязательной частью номеров российского фигуриста Ильи Климкина.

Выполнение спортивных корабликов, на первый взгляд, кажется слишком простым. Однако для движения в такой позе требуется хорошая подготовка и выносливость.