турбонасос

- турбонасос

-

турбонасо/с, -а

Слитно. Раздельно. Через дефис..

.

Синонимы:

Смотреть что такое «турбонасос» в других словарях:

-

турбонасос — турбонасос … Орфографический словарь-справочник

-

турбонасос — сущ., кол во синонимов: 1 • насос (69) Словарь синонимов ASIS. В.Н. Тришин. 2013 … Словарь синонимов

-

турбонасос — Насосный агрегат с приводом от турбины, узлы которой входят в конструкцию насоса. [ГОСТ 17398 72] Тематики насос … Справочник технического переводчика

-

турбонасос — turbininis siurblys statusas T sritis automatika atitikmenys: angl. turbine pump vok. Turbopumpe, f rus. турбонасос, m pranc. turbopompe, f … Automatikos terminų žodynas

-

турбонасос — turbininis siurblys statusas T sritis Energetika apibrėžtis Siurblys, sudarytas iš turbinos (garo, dujų ir kt.) ir jos sukamų (dažnai per reduktorių) vieno arba kelių siurblių. Naudojamas energetiniuose įrenginiuose (pvz., elektrinėse kaip… … Aiškinamasis šiluminės ir branduolinės technikos terminų žodynas

-

Турбонасос — м. Агрегат, состоящий из паровой турбины и лопастного насоса. Толковый словарь Ефремовой. Т. Ф. Ефремова. 2000 … Современный толковый словарь русского языка Ефремовой

-

турбонасос — турбонасос, турбонасосы, турбонасоса, турбонасосов, турбонасосу, турбонасосам, турбонасос, турбонасосы, турбонасосом, турбонасосами, турбонасосе, турбонасосах (Источник: «Полная акцентуированная парадигма по А. А. Зализняку») … Формы слов

-

Турбонасос — Насосный агрегат с приводом от турбины, узлы которой входят в конструкцию насоса Смотреть все термины ГОСТ 17398 72. НАСОСЫ. ТЕРМИНЫ И ОПРЕДЕЛЕНИЯ Источник: ГОСТ 17398 72. НАСОСЫ. ТЕРМИНЫ И ОПРЕДЕЛЕНИЯ … Словарь ГОСТированной лексики

-

турбонасос — турбонас ос, а … Русский орфографический словарь

-

турбонасос — (2 м); мн. турбонасо/сы, Р. турбонасо/сов … Орфографический словарь русского языка

Смотреть что такое ТУРБОНАСОС в других словарях:

ТУРБОНАСОС

турбонасос м. Агрегат, состоящий из паровой турбины и лопастного насоса.

ТУРБОНАСОС

турбонасос

сущ., кол-во синонимов: 1

• насос (69)

Словарь синонимов ASIS.В.Н. Тришин.2013.

.

Синонимы:

насос

ТУРБОНАСОС

Тусон Турбонасос Турбо Тур Тун Туба Трус Трубно Труба Трос Трон Трас Транс Торс Торос Торон Торбас Торбан Торба Тор Тоо Тонус Тонар Тон Тау Тасс Таро Танс Танбур Табун Табу Табор Сутра Сутор Сут Сурат Сура Субстр Суб Струна Строб Страус Стр Сторона Сторно Стон Стас Станс Стан Ссора Сруб Срост Соус Сотр Сосун Сост Сосна Сорус Сорт Сор Сонар Сон Собрат Собр Соборн Собор Снос Сноб Сбс Сброс Сбор Сау Сатурн Сарос Сант Сан Сабур Сабр Сабор Сабо Рута Руст Руно Руна Рубон Руан Ротон Рота Рот Рост Росс Росно Роса Рон Робуст Робот Роба Раут Раус Раст Рао Рант Рано Раб Оун Отсос Отруб Относ Отброс Отбор Отар Остро Остан Ост Осот Особа Оса Орун Орт Орс Орнат Орн Оон Оброн Обратно Обрат Обр Обора Обнос Оао Нутро Нут Нус Нтр Нто Ноу Нота Ностро Нос Нора Наутро Наус Наур Натр Нато Наст Насос Нарост Наос Наброс Набор Наб Бутс Бутон Бутан Бут Бурт Бурса Бурно Бурат Буран Бура Бур Бунт Буна Бтр Брут Брусс Брус Бруно Брон Браун Брат Брасс Брас Бра Бот Бостон Босс Босот Борт Борона Борн Борат Уба Убор Унос Унр Унт Уран Бор Бонус Бон Боа Батун Батор Батоно Батон Бат Бастр Басон Урат Урбан Бас Барс Урна Барон Урон Уса Уста Устно Утор Утро Баро Барн Утроба Бант Астрон Астр Артос Арт Арно Аоот Утробно Аборт Ант Анус Аон Арон Асс Астро Асу Аут Бар… смотреть

ТУРБОНАСОС

1) Орфографическая запись слова: турбонасос2) Ударение в слове: турбонас`ос3) Деление слова на слоги (перенос слова): турбонасос4) Фонетическая транскр… смотреть

ТУРБОНАСОС

корень — ТУРБ; соединительная гласная — О; корень — НАСОС; нулевое окончание;Основа слова: ТУРБОНАСОСВычисленный способ образования слова: Сложение осн… смотреть

ТУРБОНАСОС

Насосный агрегат с приводом от турбины, узлы которой входят в конструкцию насосаСмотреть все термины ГОСТ 17398-72. НАСОСЫ. ТЕРМИНЫ И ОПРЕДЕЛЕНИЯИсточн… смотреть

ТУРБОНАСОС

м. turbopompa f — турбонасос высокого давления- перекачивающий турбонасос- питающий турбонасос- топливный турбонасос- циркуляционный турбонасос

ТУРБОНАСОС

ту́рбонасо́с,

ту́рбонасо́сы,

ту́рбонасо́са,

ту́рбонасо́сов,

ту́рбонасо́су,

ту́рбонасо́сам,

ту́рбонасо́с,

ту́рбонасо́сы,

ту́рбонасо́сом,

ту́рбонасо́сами,

ту́рбонасо́се,

ту́рбонасо́сах

(Источник: «Полная акцентуированная парадигма по А. А. Зализняку»)

.

Синонимы:

насос… смотреть

ТУРБОНАСОС

Ударение в слове: турбонас`осУдарение падает на букву: оБезударные гласные в слове: турбонас`ос

ТУРБОНАСОС

(2 м); мн. турбонасо/сы, Р. турбонасо/совСинонимы: насос

ТУРБОНАСОС

turbine pump, pump-turbine* * *турбонасо́с м.turbo-pump* * *turbo-pumpСинонимы: насос

ТУРБОНАСОС

ту`рбонасо’с, ту`рбонасо’сы, ту`рбонасо’са, ту`рбонасо’сов, ту`рбонасо’су, ту`рбонасо’сам, ту`рбонасо’с, ту`рбонасо’сы, ту`рбонасо’сом, ту`рбонасо’сами, ту`рбонасо’се, ту`рбонасо’сах… смотреть

ТУРБОНАСОС

1) pump-turbine2) turbo-pumpСинонимы: насос

ТУРБОНАСОС

Начальная форма — Турбонасос, винительный падеж, единственное число, мужской род, неодушевленное

ТУРБОНАСОС

ТУРБОНАСОС м. Агрегат, состоящий из паровой турбины и лопастного насоса.

ТУРБОНАСОС

техн.

турбопо́мпа

— многоступенчатый турбонасос

Синонимы:

насос

турбонасос

→

турбонасос — существительное, именительный п., муж. p., ед. ч.

↳

турбонасос — существительное, винительный п., муж. p., ед. ч.

Часть речи: существительное

| Единственное число | Множественное число | |

|---|---|---|

| Им. |

турбонасос |

турбонасосы |

| Рд. |

турбонасоса |

турбонасосов |

| Дт. |

турбонасосу |

турбонасосам |

| Вн. |

турбонасос |

турбонасосы |

| Тв. |

турбонасосом |

турбонасосами |

| Пр. |

турбонасосе |

турбонасосах |

Если вы нашли ошибку, пожалуйста, выделите фрагмент текста и нажмите Ctrl+Enter.

Слова русского языка,

поиск и разбор слов онлайн

турбонасос

Правильно слово пишется: турбонасос

Всего в слове 10 букв, 4 гласных, 6 согласных, 4 слога.

Гласные: у, о, а, о;

Согласные: т, р, б, н, с, с.

Номера букв в слове

Номера букв в слове «турбонасос» в прямом и обратном порядке:

- 10

т

1 - 9

у

2 - 8

р

3 - 7

б

4 - 6

о

5 - 5

н

6 - 4

а

7 - 3

с

8 - 2

о

9 - 1

с

10

Разбор по составу

Разбор по составу (морфемный разбор) слова турбонасос делается следующим образом:

турбонасос

Морфемы слова: турб, насос — корни, о — соединительная гласная, нулевое окончание, турб, насос — основы.

Разбор слова «Турбонасос»

На чтение 1 мин.

Значение слова «Турбонасос»

— агрегат, состоящий из паровой турбины и лопастного насоса

Содержание

- Транскрипция слова

- MFA Международная транскрипция

- Цветовая схема слова

Транскрипция слова

[турбанасо́с]

MFA Международная транскрипция

[ˌturbənɐˈsos]

| т | [т] | согласный, глухой парный, твердый парный |

| у | [у] | гласный, безударный |

| р | [р] | согласный, звонкий непарный (сонорный), твердый парный |

| б | [б] | согласный, звонкий парный, твердый парный |

| о | [а] | гласный, безударный |

| н | [н] | согласный, звонкий непарный (сонорный), твердый парный |

| а | [а] | гласный, безударный |

| с | [с] | согласный, глухой парный, твердый парный |

| о | [́о] | гласный, ударный |

| с | [с] | согласный, глухой парный, твердый парный |

Букв: 10 Звуков: 10

Цветовая схема слова

турбонасос

Как правильно пишется «Турбонасос»

турбонасо́с

турбонасо́с, -а

Как правильно перенести «Турбонасос»

турбонасо́с

Часть речи

Часть речи слова «турбонасос» — Имя существительное

Морфологические признаки.

турбонасос (именительный падеж, единственного числа)

Постоянные признаки:

- нарицательное

- неодушевлённое

- мужской

- 2-e склонение

Непостоянные признаки:

- именительный падеж

- единственного числа

Может относится к разным членам предложения.

Склонение слова «Турбонасос»

| Падеж | Единственное число | Множественное число |

|---|---|---|

| Именительный Кто? Что? |

турбонасос | турбонасосы |

| Родительный Кого? Чего? |

турбонасоса | турбонасосов |

| Дательный Кому? Чему? |

турбонасосу | турбонасосам |

| Винительный (неод.) Кого? Что? |

турбонасос | турбонасосы |

| Творительный Кем? Чем? |

турбонасосом | турбонасосами |

| Предложный О ком? О чём? |

турбонасосе | турбонасосах |

Разбор по составу слова «Турбонасос»

Состав слова «турбонасос»:

корень — [турб], соединительная гласная — [о], корень — [насос], нулевое окончание — [ ]

Проверьте свои знания русского языка

Категория: Русский язык

Русский язык

Тест на тему “Орфограмма”

1 / 5

Что такое орфограмма?

Раздел языкознания

Иностранный язык

Место в слове, где можно допустить ошибку, написав неправильную букву

Начальная буква в слове

2 / 5

Какая орфограмма наблюдается в слове «жизнь»?

Большая буква в начале предложения

Правописание сочетаний «жи-ши», «ча-ща», «чу-щу»

Правописание мягкого знака

Правописание сочетаний «чк-чн»

3 / 5

Как нужно подчеркивать место, где можно совершить ошибку?

Одной чертой

Двумя чертами

Волнистой линией

Двумя волнистыми линиями

4 / 5

Укажите неверное утверждение.

Орфограмма с греческого переводится как «правильно писать»

Орфографическая зоркость – это умение видеть слово, в котором есть орфограмма

Наличие большого количества орфограмм способствовало появлению такой науки, как орфография

Условие, по которому пишется та, а не другая буква, подчеркивается волнистой линией

5 / 5

Какая орфограмма наблюдается в слове «сердце»?

Проверяемые безударные гласные в корне слова

Непроверяемые безударные гласные в корне слова

Имена собственные

Непроизносимые согласные в корне слова

Синонимы к слову «турбонасос»

теплообменник

пневмопривод

рециркуляция

Предложения со словом «турбонасос»

- Отсоединился последний кабель, и в дело вступил турбонасос мощностью 540 лошадиных сил, который, давая 4000 оборотов в минуту, каждую секунду накачивал в камеру сгорания двигателя ракеты 125 литров кислородно-спиртовой смеси.

Вальтер Дорнбергер, Фау-2. Сверхоружие Третьего рейха. 1930-1945

- Это значило, что за городом включены турбонасосы с мощнейшим энергопотреблением, разгоняющие смог над городом, и воздух сегодня платный.

Геннадий Черников, Мегаполис ноль

From Wikipedia, the free encyclopedia

This article is about the fuel pump. For turbine devices for producing a high vacuum, see Turbomolecular pump. For the vehicular air pump, see Turbocharger and Supercharger.

A turbopump is a propellant pump with two main components: a rotodynamic pump and a driving gas turbine, usually both mounted on the same shaft, or sometimes geared together. They were initially developed in Germany in the early 1940s. The purpose of a turbopump is to produce a high-pressure fluid for feeding a combustion chamber or other use.

There are two types of turbopumps: a centrifugal pump, where the pumping is done by throwing fluid outward at high speed, or an axial-flow pump, where alternating rotating and static blades progressively raise the pressure of a fluid.

Axial-flow pumps have small diameters but give relatively modest pressure increases. Although multiple compression stages are needed, axial flow pumps work well with low-density fluids. Centrifugal pumps are far more powerful for high-density fluids but require large diameters for low-density fluids.

History[edit]

The V-2 rocket used a circular turbopump to pressurize the propellant.

Early development[edit]

High-pressure pumps for larger missiles had been discussed by rocket pioneers such as Hermann Oberth.[specify] In mid-1935 Wernher von Braun initiated a fuel pump project at the southwest German firm Klein, Schanzlin & Becker that was experienced in building large fire-fighting pumps.[1]: 80 The V-2 rocket design used hydrogen peroxide decomposed through a Walter steam generator to power the uncontrolled turbopump[1]: 81 produced at the Heinkel plant at Jenbach,[2] so V-2 turbopumps and combustion chamber were tested and matched to prevent the pump from overpressurizing the chamber.[1]: 172 The first engine fired successfully in September, and on August 16, 1942, a trial rocket stopped in mid-air and crashed due to a failure in the turbopump.[1][verification needed] The first successful V-2 launch was on October 3, 1942.[3]

Development from 1947 to 1949[edit]

The principal engineer for turbopump development at Aerojet was George Bosco. During the second half of 1947, Bosco and his group learned about the pump work of others and made preliminary design studies. Aerojet representatives visited Ohio State University where Florant was working on hydrogen pumps, and consulted Dietrich Singelmann, a German pump expert at Wright Field. Bosco subsequently used Singelmann’s data in designing Aerojet’s first hydrogen pump.[4]

By mid-1948, Aerojet had selected centrifugal pumps for both liquid hydrogen and liquid oxygen. They obtained some German radial-vane pumps from the Navy and tested them during the second half of the year.[4]

By the end of 1948, Aerojet had designed, built, and tested a liquid hydrogen pump (15 cm diameter). Initially, it used ball bearings that were run clean and dry, because the low temperature made conventional lubrication impractical. The pump was first operated at low speeds to allow its parts to cool down to operating temperature. When temperature gauges showed that liquid hydrogen had reached the pump, an attempt was made to accelerate from 5000 to 35 000 revolutions per minute. The pump failed and examination of the pieces pointed to a failure of the bearing, as well as the impeller. After some testing, super-precision bearings, lubricated by oil that was atomized and directed by a stream of gaseous nitrogen, were used. On the next run, the bearings worked satisfactorily but the stresses were too great for the brazed impeller and it flew apart. A new one was made by milling from a solid block of aluminum. The next two runs with the new pump were a great disappointment; the instruments showed no significant flow or pressure rise. The problem was traced to the exit diffuser of the pump, which was too small and insufficiently cooled during the cool-down cycle so that it limited the flow. This was corrected by adding vent holes in the pump housing; the vents were opened during cool down and closed when the pump was cold. With this fix, two additional runs were made in March 1949 and both were successful. Flow rate and pressure were found to be in approximate agreement with theoretical predictions. The maximum pressure was 26 atmospheres (26 atm (2.6 MPa; 380 psi)) and the flow was 0.25 kilogram per second.[4]

After 1949[edit]

The Space Shuttle main engine’s turbopumps spun at over 30,000 rpm, delivering 150 lb (68 kg) of liquid hydrogen and 896 lb (406 kg) of liquid oxygen to the engine per second.[5] The Electron Rocket’s Rutherford became the first engine to use an electrically-driven turbopumps in flight in 2018. [6]

Centrifugal turbopumps[edit]

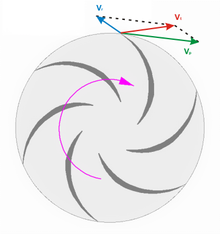

In centrifugal turbopumps a rotating disk throws the fluid to the rim.

Most turbopumps are centrifugal — the fluid enters the pump near the axis and the rotor accelerates the fluid to high speed. The fluid then passes through a diffuser which is a progressively enlarging pipe, which permits recovery of the dynamic pressure. The diffuser turns the high kinetic energy into high pressures (hundreds of bars is not uncommon), and if the outlet backpressure is not too high, high flow rates can be achieved.

Axial turbopumps[edit]

Axial turbopumps also exist. In this case the axle essentially has propellers attached to the shaft, and the fluid is forced by these parallel with the main axis of the pump. Generally, axial pumps tend to give much lower pressures than centrifugal pumps, and a few bars is not uncommon. They are, however, still useful – axial pumps are commonly used as «inducers» for centrifugal pumps, which raise the inlet pressure of the centrifugal pump enough to prevent excessive cavitation from occurring therein.

Complexities of centrifugal turbopumps[edit]

Turbopumps have a reputation for being extremely hard to design to get optimal performance. Whereas a well engineered and debugged pump can manage 70–90% efficiency, figures less than half that are not uncommon. Low efficiency may be acceptable in some applications, but in rocketry this is a severe problem. Turbopumps in rockets are important and problematic enough that launch vehicles using one have been caustically described as a «turbopump with a rocket attached»–up to 55% of the total cost has been ascribed to this area.[7]

Common problems include:

- excessive flow from the high-pressure rim back to the low-pressure inlet along the gap between the casing of the pump and the rotor,

- excessive recirculation of the fluid at inlet,

- excessive vortexing of the fluid as it leaves the casing of the pump,

- damaging cavitation to impeller blade surfaces in low-pressure zones.

In addition, the precise shape of the rotor itself is critical.

Driving turbopumps[edit]

Steam turbine-powered turbopumps are employed when there is a source of steam, e.g. the boilers of steam ships. Gas turbines are usually used when electricity or steam is not available and place or weight restrictions permit the use of more efficient sources of mechanical energy.

One of such cases are rocket engines, which need to pump fuel and oxidizer into their combustion chamber. This is necessary for large liquid rockets, since forcing the fluids or gases to flow by simple pressurizing of the tanks is often not feasible; the high pressure needed for the required flow rates would need strong and thereby heavy tanks.

Ramjet motors are also usually fitted with turbopumps, the turbine being driven either directly by external freestream ram air or internally by airflow diverted from combustor entry. In both cases the turbine exhaust stream is dumped overboard.

See also[edit]

- Turboexpander

- Gas-generator cycle

- Staged combustion cycle

- Expander cycle

References[edit]

- ^ a b c d Neufeld, Michael J. (1995). The Rocket and the Reich. The Smithsonian Institution. pp. 80–1, 156, 172. ISBN 0-674-77650-X.

- ^ Ordway, Frederick I, III; Sharpe, Mitchell R (1979). The Rocket Team. Apogee Books Space Series 36. New York: Thomas Y. Crowell. p. 140. ISBN 1-894959-00-0. Archived from the original on 2012-03-04.

- ^ Dornberger, Walter (1954) [1952]. Der Schuss ins Weltall / V-2. US translation from German. Esslingan; New York: Bechtle Verlag (German); Viking Press (English). p. 17.

- ^ a b c «Liquid Hydrogen as a Propulsion Fuel, 1945-1959». NASA. Archived from the original on 2017-12-25. Retrieved 2017-07-12.

- ^ Hill, P & Peterson, C.(1992) Mechanics and Thermodynamics of Propulsion. New York: Addison-Wesley ISBN 0-201-14659-2

- ^ Brügge, Norbert. «Electron Propulsion». B14643.de. Archived from the original on 26 January 2018. Retrieved 20 September 2016.

- ^ Wu, Yulin, et al. Vibration of hydraulic machinery. Berlin: Springer, 2013.

External links[edit]

Wikimedia Commons has media related to Turbopumps.

- Book of Rocket Propulsion

- M. L. «Joe» Stangeland (Summer 1988). «Turbopumps for Liquid Rocket Engines». Threshold – Engineering Journal of Power Technology. Rocketdyne. Archived from the original on 2009-09-24.

From Wikipedia, the free encyclopedia

This article is about the fuel pump. For turbine devices for producing a high vacuum, see Turbomolecular pump. For the vehicular air pump, see Turbocharger and Supercharger.

A turbopump is a propellant pump with two main components: a rotodynamic pump and a driving gas turbine, usually both mounted on the same shaft, or sometimes geared together. They were initially developed in Germany in the early 1940s. The purpose of a turbopump is to produce a high-pressure fluid for feeding a combustion chamber or other use.

There are two types of turbopumps: a centrifugal pump, where the pumping is done by throwing fluid outward at high speed, or an axial-flow pump, where alternating rotating and static blades progressively raise the pressure of a fluid.

Axial-flow pumps have small diameters but give relatively modest pressure increases. Although multiple compression stages are needed, axial flow pumps work well with low-density fluids. Centrifugal pumps are far more powerful for high-density fluids but require large diameters for low-density fluids.

History[edit]

The V-2 rocket used a circular turbopump to pressurize the propellant.

Early development[edit]

High-pressure pumps for larger missiles had been discussed by rocket pioneers such as Hermann Oberth.[specify] In mid-1935 Wernher von Braun initiated a fuel pump project at the southwest German firm Klein, Schanzlin & Becker that was experienced in building large fire-fighting pumps.[1]: 80 The V-2 rocket design used hydrogen peroxide decomposed through a Walter steam generator to power the uncontrolled turbopump[1]: 81 produced at the Heinkel plant at Jenbach,[2] so V-2 turbopumps and combustion chamber were tested and matched to prevent the pump from overpressurizing the chamber.[1]: 172 The first engine fired successfully in September, and on August 16, 1942, a trial rocket stopped in mid-air and crashed due to a failure in the turbopump.[1][verification needed] The first successful V-2 launch was on October 3, 1942.[3]

Development from 1947 to 1949[edit]

The principal engineer for turbopump development at Aerojet was George Bosco. During the second half of 1947, Bosco and his group learned about the pump work of others and made preliminary design studies. Aerojet representatives visited Ohio State University where Florant was working on hydrogen pumps, and consulted Dietrich Singelmann, a German pump expert at Wright Field. Bosco subsequently used Singelmann’s data in designing Aerojet’s first hydrogen pump.[4]

By mid-1948, Aerojet had selected centrifugal pumps for both liquid hydrogen and liquid oxygen. They obtained some German radial-vane pumps from the Navy and tested them during the second half of the year.[4]

By the end of 1948, Aerojet had designed, built, and tested a liquid hydrogen pump (15 cm diameter). Initially, it used ball bearings that were run clean and dry, because the low temperature made conventional lubrication impractical. The pump was first operated at low speeds to allow its parts to cool down to operating temperature. When temperature gauges showed that liquid hydrogen had reached the pump, an attempt was made to accelerate from 5000 to 35 000 revolutions per minute. The pump failed and examination of the pieces pointed to a failure of the bearing, as well as the impeller. After some testing, super-precision bearings, lubricated by oil that was atomized and directed by a stream of gaseous nitrogen, were used. On the next run, the bearings worked satisfactorily but the stresses were too great for the brazed impeller and it flew apart. A new one was made by milling from a solid block of aluminum. The next two runs with the new pump were a great disappointment; the instruments showed no significant flow or pressure rise. The problem was traced to the exit diffuser of the pump, which was too small and insufficiently cooled during the cool-down cycle so that it limited the flow. This was corrected by adding vent holes in the pump housing; the vents were opened during cool down and closed when the pump was cold. With this fix, two additional runs were made in March 1949 and both were successful. Flow rate and pressure were found to be in approximate agreement with theoretical predictions. The maximum pressure was 26 atmospheres (26 atm (2.6 MPa; 380 psi)) and the flow was 0.25 kilogram per second.[4]

After 1949[edit]

The Space Shuttle main engine’s turbopumps spun at over 30,000 rpm, delivering 150 lb (68 kg) of liquid hydrogen and 896 lb (406 kg) of liquid oxygen to the engine per second.[5] The Electron Rocket’s Rutherford became the first engine to use an electrically-driven turbopumps in flight in 2018. [6]

Centrifugal turbopumps[edit]

In centrifugal turbopumps a rotating disk throws the fluid to the rim.

Most turbopumps are centrifugal — the fluid enters the pump near the axis and the rotor accelerates the fluid to high speed. The fluid then passes through a diffuser which is a progressively enlarging pipe, which permits recovery of the dynamic pressure. The diffuser turns the high kinetic energy into high pressures (hundreds of bars is not uncommon), and if the outlet backpressure is not too high, high flow rates can be achieved.

Axial turbopumps[edit]

Axial turbopumps also exist. In this case the axle essentially has propellers attached to the shaft, and the fluid is forced by these parallel with the main axis of the pump. Generally, axial pumps tend to give much lower pressures than centrifugal pumps, and a few bars is not uncommon. They are, however, still useful – axial pumps are commonly used as «inducers» for centrifugal pumps, which raise the inlet pressure of the centrifugal pump enough to prevent excessive cavitation from occurring therein.

Complexities of centrifugal turbopumps[edit]

Turbopumps have a reputation for being extremely hard to design to get optimal performance. Whereas a well engineered and debugged pump can manage 70–90% efficiency, figures less than half that are not uncommon. Low efficiency may be acceptable in some applications, but in rocketry this is a severe problem. Turbopumps in rockets are important and problematic enough that launch vehicles using one have been caustically described as a «turbopump with a rocket attached»–up to 55% of the total cost has been ascribed to this area.[7]

Common problems include:

- excessive flow from the high-pressure rim back to the low-pressure inlet along the gap between the casing of the pump and the rotor,

- excessive recirculation of the fluid at inlet,

- excessive vortexing of the fluid as it leaves the casing of the pump,

- damaging cavitation to impeller blade surfaces in low-pressure zones.

In addition, the precise shape of the rotor itself is critical.

Driving turbopumps[edit]

Steam turbine-powered turbopumps are employed when there is a source of steam, e.g. the boilers of steam ships. Gas turbines are usually used when electricity or steam is not available and place or weight restrictions permit the use of more efficient sources of mechanical energy.

One of such cases are rocket engines, which need to pump fuel and oxidizer into their combustion chamber. This is necessary for large liquid rockets, since forcing the fluids or gases to flow by simple pressurizing of the tanks is often not feasible; the high pressure needed for the required flow rates would need strong and thereby heavy tanks.

Ramjet motors are also usually fitted with turbopumps, the turbine being driven either directly by external freestream ram air or internally by airflow diverted from combustor entry. In both cases the turbine exhaust stream is dumped overboard.

See also[edit]

- Turboexpander

- Gas-generator cycle

- Staged combustion cycle

- Expander cycle

References[edit]

- ^ a b c d Neufeld, Michael J. (1995). The Rocket and the Reich. The Smithsonian Institution. pp. 80–1, 156, 172. ISBN 0-674-77650-X.

- ^ Ordway, Frederick I, III; Sharpe, Mitchell R (1979). The Rocket Team. Apogee Books Space Series 36. New York: Thomas Y. Crowell. p. 140. ISBN 1-894959-00-0. Archived from the original on 2012-03-04.

- ^ Dornberger, Walter (1954) [1952]. Der Schuss ins Weltall / V-2. US translation from German. Esslingan; New York: Bechtle Verlag (German); Viking Press (English). p. 17.

- ^ a b c «Liquid Hydrogen as a Propulsion Fuel, 1945-1959». NASA. Archived from the original on 2017-12-25. Retrieved 2017-07-12.

- ^ Hill, P & Peterson, C.(1992) Mechanics and Thermodynamics of Propulsion. New York: Addison-Wesley ISBN 0-201-14659-2

- ^ Brügge, Norbert. «Electron Propulsion». B14643.de. Archived from the original on 26 January 2018. Retrieved 20 September 2016.

- ^ Wu, Yulin, et al. Vibration of hydraulic machinery. Berlin: Springer, 2013.

External links[edit]

Wikimedia Commons has media related to Turbopumps.

- Book of Rocket Propulsion

- M. L. «Joe» Stangeland (Summer 1988). «Turbopumps for Liquid Rocket Engines». Threshold – Engineering Journal of Power Technology. Rocketdyne. Archived from the original on 2009-09-24.